The overall integration of the experiment includes the design and construction of the intelligent laboratory, the integration of the laboratory system and its automatic control system, the configuration, scheme and supply of instruments and equipment, and the design and supply of samplers.

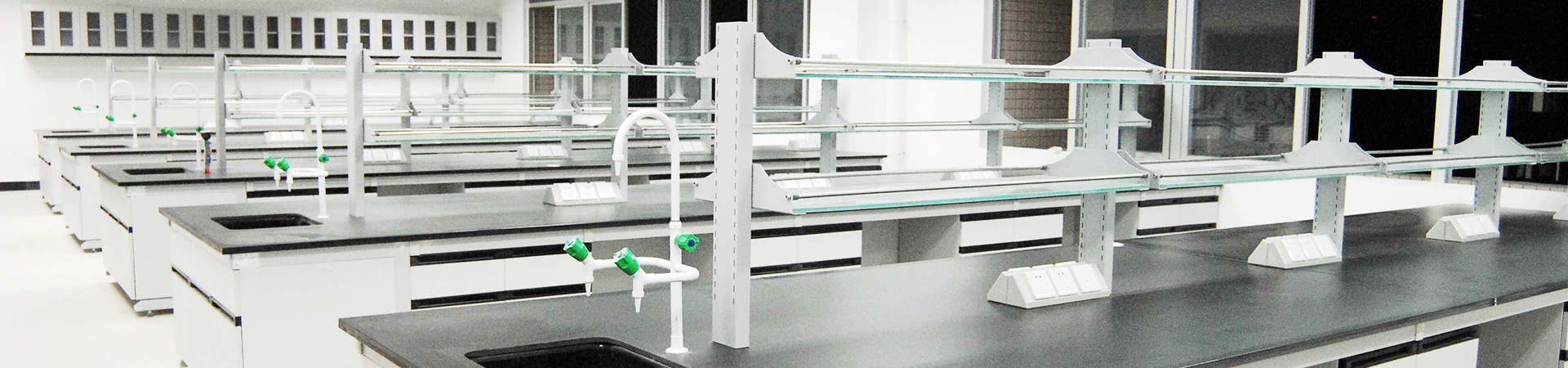

Product display

Built a standard laboratory furniture production line, imported a complete set of equipment, from cutting plate, folding, drilling, welding, grinding, phosphorus washing, acidizing, spraying and other integrated production lines.

Laboratory gas system

Gas system supply flow

- Supply air source

(Primary decompression) - Individual room control

Valve, pressure display - Secondary decompression

- Terminal valve

The primary decompression of the gas source adopts an automatic switching system, which can automatically switch to the standby gas source, and the linkage with the mortgage alarm can remind the timely replacement of the gas cylinder, and the secondary decompression can ensure the stable demand of the pressure flow of the instrument. The room is equipped with general control valve and pressure gauge, with emergency cut off air source. Leakage tips do not affect the function of other instruments.

The gas is transported from the gas cylinder room to the gas room through the ceiling. The combustible gas pipeline does not pass through the room that does not use the gas. After entering the room, it is transported to the end gas point along the wall/functional column/ground. In order to ensure the purity of the gas and the tightness of the pipeline system, all the pipelines are made of BA standard stainless steel pipes on the inner surface. Pressure regulating valve, switch valve, sleeve welding parts, metal hose using SS316 material products. Combustible gas system is equipped with explosion-proof check valve to avoid gas backflow and danger. Combustible gas, toxic gas room set up the corresponding gas detector, detect the room gas concentration, local alarm and transmission signal to the monitoring host, to avoid the danger of gas accumulation.

Hvac system

The main purpose of laboratory ventilation system is to provide a safe and comfortable working environment, reduce the possibility of laboratory personnel exposed to dangerous air, is to achieve indoor and outdoor air environment quality assurance of a building environment control technology, is the entire laboratory design and construction process in the largest scale, one of the most influential systems. Whether the laboratory ventilation system is perfect or not has a significant impact on the laboratory environment, the health of laboratory personnel and the operation and maintenance of experimental equipment.

- Conduit

- Exhaust fan

- Integrated space

Laboratory ventilation design objectives:

Through the risk control system

Laboratory intelligence is not only a technology, but also a concept, a trend, it will bring the laboratory world into a new era, change and affect people\\\\\\\'s ideas and ways of working, reflects the modern management model of the laboratory, fully deduces the essence of laboratory science and technology.

-

Variable air volume controlAccording to the measurement value of the fume hood sensor, the opening of the exhaust air variable air volume valve of the fume hood is automatically adjusted to ensure the constant wind speed on the fume hood surface, and the supply air volume is interlock controlled to maintain negative pressure.

-

Temperature controlAccording to the comparison between the air supply temperature and the set value, PID adjusts the opening of the electric water valve to ensure the constant air supply temperature.

-

Fan frequency conversion control modeAdopt static pressure mode, according to the actual use of the end equipment to automatically adjust the fan air volume.

The laboratory control system is composed of central operation station, controller (DDC, PLC), inverter, sensor (temperature, humidity, pressure), actuator and variable air volume risk control system (infrared controller, variable air volume control valve, liquid control panel, displacement sensor).

Laboratory equipment

Laboratory instrument is a comprehensive product of a variety of science and technology, a wide variety of varieties, widely used, and constantly updated, there are a variety of classification methods. According to the purpose and use, the main scientific research equipment, testing equipment, teaching equipment, medical equipment and so on. Closed loop sampling device is used to collect gaseous or liquid materials in production, these materials are generally flammable and explosive, high temperature and high pressure, slightly toxic and highly toxic characteristics. In order to ensure production safety and control environmental pollution, it is necessary to install a professional sampler at the sampling site of the production device in order to check product quality and adjust the production process.

- Liquid sampler

The sealed sampler fully embodies the people-oriented design concept, and the professionally designed sampling valve is used to collect liquid samples of different temperatures, pressures and viscoses. Features: Meet the sampling requirements of various liquid media. - Gas sampler

With the general popularization of the sampler, it will certainly help to achieve the corresponding benefits of safety, environmental protection and low carbon in the sampling of petrochemical equipment in China. - Liquefied gas sampler

Closed loop sampling, no need to clean the sampling pipe, effectively reduce the material loss, to avoid sampling samples and outside contact, so that the collected samples will not be contaminated by the outside world. Can be equipped with nitrogen purging to ensure no sample residue in the sampling channel.